All our production takes place at state-of-the-art processing sites, in full compliance with the strictest European standards for the food sector, both in terms of hygiene and preservation.

Over the years we have renovated, updated and expanded our production areas, dedicating them to fresh meat processing. We are always at the forefront in adopting innovative production processes and packaging systems that respect the raw material and the environment.

The raw materials pass from the reception and storage cells to the first processing through “forward” and non-crossing routes.

The meat is then processed and packaged in ‘clean rooms’ (departments with controlled air and temperature filtering systems) and finally labelled and prepared for dispatch to points of sale. A modern supervision system for the plants and energy distribution, active 24/7 and equipped with alarm systems directed at the company managers, oversees the continuous monitoring and recording of data so that the best conditions are in place for processing and storing the product, from entry to dispatch.

Thanks to a specially designed computer system, we can control and manage the traceability of each individual product at all its stages of processing, from the entry of the raw material to its processing, and to the finished product ready for dispatch.

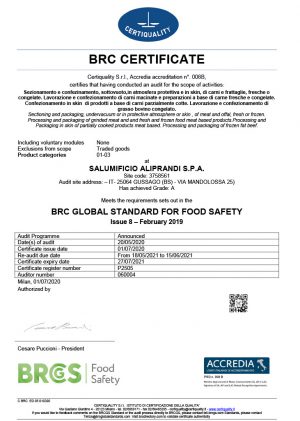

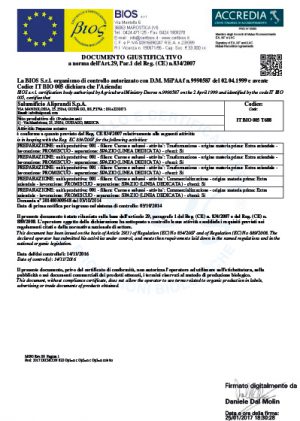

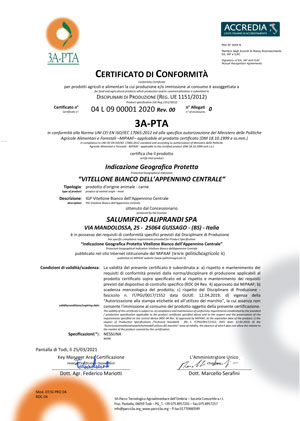

Certifications

Sustainable company

ROSSA | human-made brands

ROSSA | human-made brands